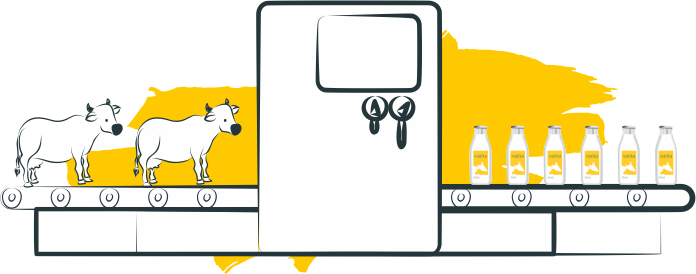

From the dairy farms to your table, in just a day or two, is not an easy matter. But for your benefit, we revel in living up to the challenge. You deserve fresh products. However, this does not mean that we compromise on the quality. Matrika is not just fresh, it is also pure.

So, where does it all begin? With the cows, of course. And we wouldn’t really be able to make this work without our God mother, the Land/Farm. You can find out more about it here.